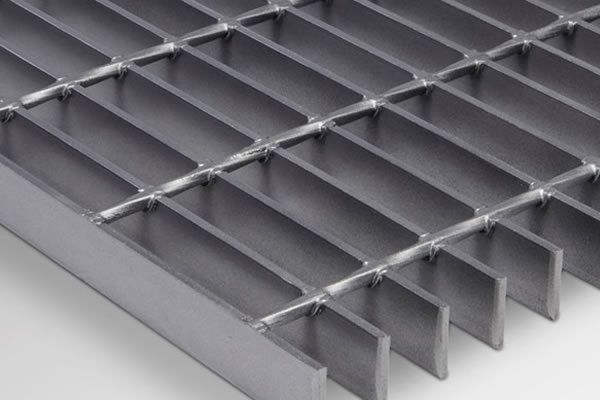

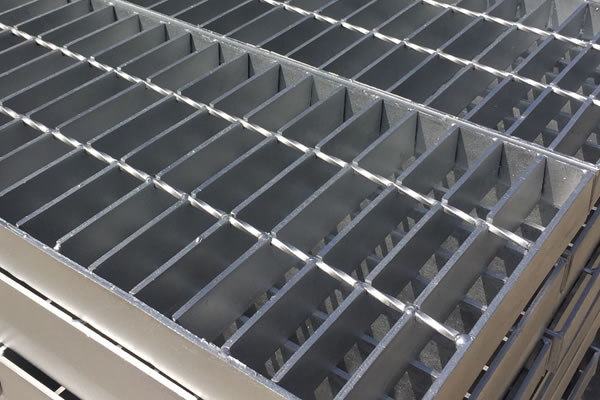

Galvanized Steel Grating

Made from carbon steel and coated with zinc through galvanization after welding, this grating offers enhanced corrosion resistance. Ideal for outdoor or industrial settings, it balances affordability with the strength and durability of steel, making it a cost-effective choice for heavy-duty use.