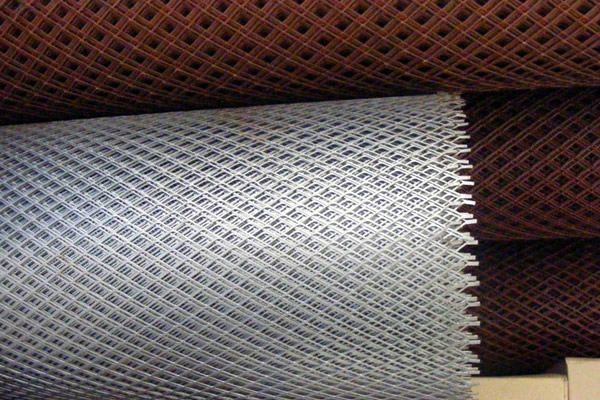

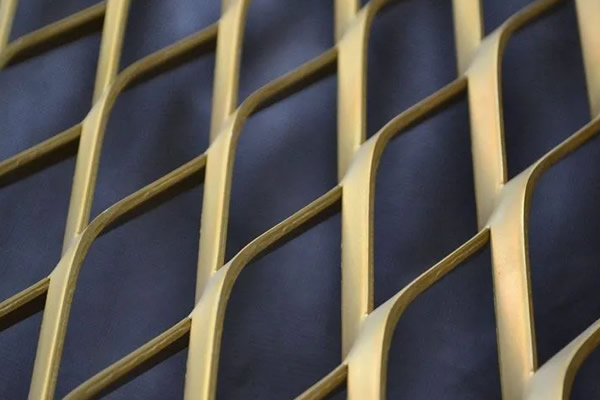

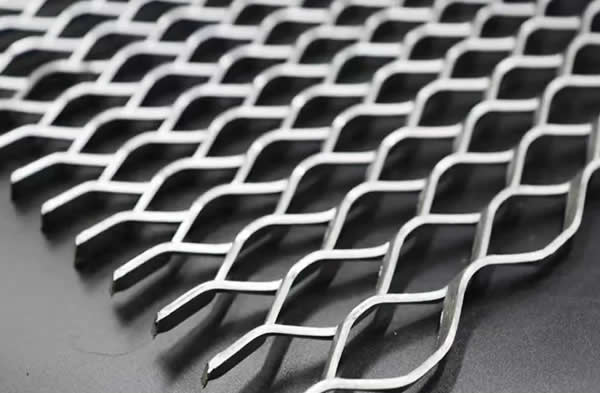

Steel Expanded Metal

Available in high carbon and low carbon steel, this type can be galvanized or plastic-coated. The galvanized variant is made by cutting and stretching carbon steel, then galvanizing it for corrosion resistance. This makes it economical and durable, often priced lower than stainless steel and copper alloys. Ideal for industrial uses like walkways and fencing, it offers strength and rust protection. It’s particularly cost-effective for heavy-duty, corrosion-resistant applications.